Meeting Your Hardware Requirements with OEM Services

“What is the benefit of using OEM Services over purchasing off-the-shelf products?” I can answer this question easier with an example. Just last week, Mr. Zhang, who is a procurement manager in a machinery plant from Hebei, called me. He was looking to buy bearing housings with certain specifications, but the available options did not offer sufficient protection against high temperatures and corrosion. Using our OEM Services, we designed and manufactured a custom bearing housing in three weeks, and it was only 12% more than the standard price. This provided him a 40% increase in equipment lifespan. That is the essence of OEM Services: achieving exact customization.

In the hardware industry, OEM Services have clear benefits in three key areas: technical flexibility, cost efficiency, and supply chain consistency. For example, take the case of a Tangshan Jiaheng Technology Co., Ltd. customer that we helped with an international branded OEM. Their initial order was based on generic hardware components resulting in very low assembly efficiency. Thanks to OEM Services, our engineering team altered the connector interface to enable a client installation time reduction from 25 minutes to 8 minutes. These modifications also reduced annual wage expenditure by more than 800,000 RMB. Such comprehensive changes are not possible when using standard off-the-shelf products.

Looking at OEM Services Value Dimensions from the Lens of Hardware Engineering

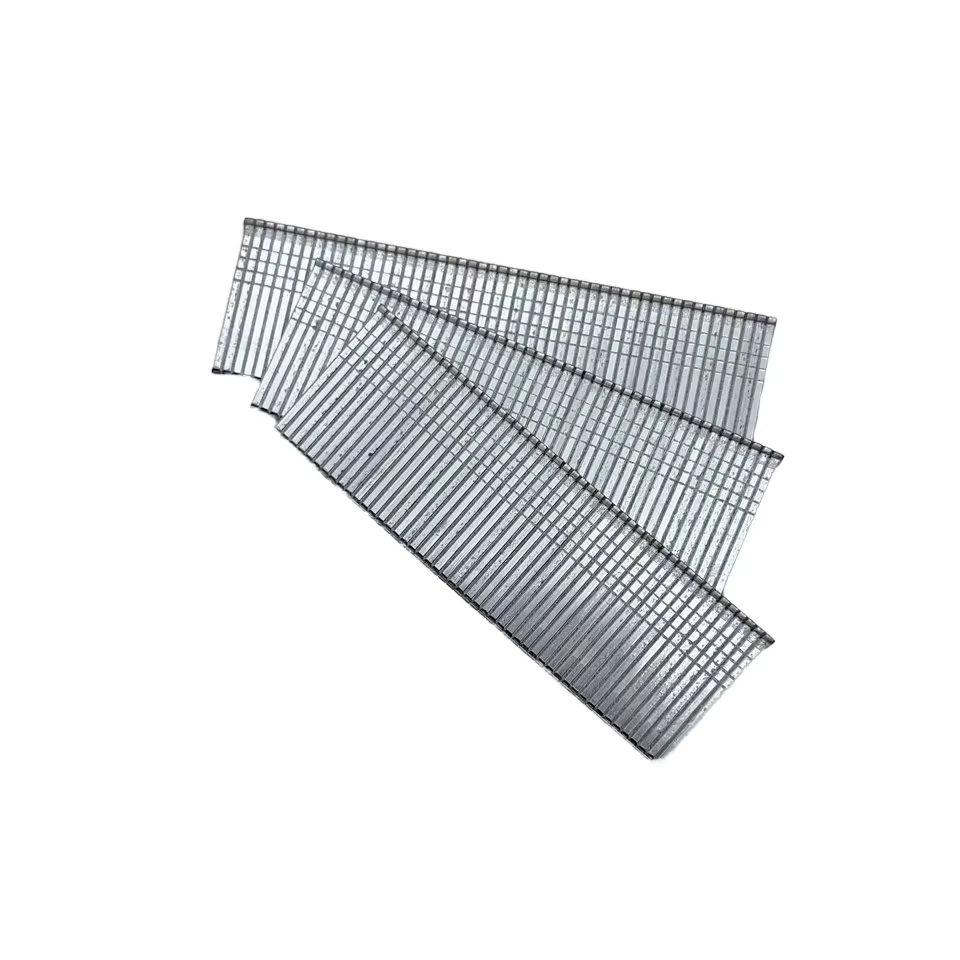

I believe that quality control on OEM Services is one of the areas that gets overlooked the most by my industry colleagues. There was a customer last year on a wind power project I worked on that needed one of their components fastened specially. Not only did they require ISO 898-1 class 10.9 bolts, they also needed them to function at -40° C. Using OEM Services’ fast flexible production capabilities, we altered the alloy blend and the heat treatment cycles. It passed independent tests and exceeded industry norms on fatigue life by 30%. Hardware solutions reinforce my belief that to optimize devices, products need not be forced to engineering requirements, but instead, should be engineered to necessities.

Investigating OEM Services shows extra value that is usually missed. An auto parts supplier comes to mind from my previous cost assessment. While custom molds had a higher up front expense, the lower secondary processing costs along with reduced defects, improved assembly efficiency, and total 18 month payback period made the incremental costs pay off. More importantly, off-the-shelf procurements do not guarantee confidentiality protection. OEM services do, which is critical for safeguarding proprietary designs.

Steps Towards Improving Utilization of OEM Services

When initiating a partnership with an OEM, I always recommend a three-step process starting with Define Requirements → Prototype Validation → Mass Production Optimization. I recall working with the elevator manufacturers in 2019. We assisted them in redesigning the safety clamp components which resulted in three rounds of prototyping. This enabled the mass production stage to achieve perfect zero-defect output. “A successful OEM partnership is like the meshing of precision gears,” comments Engineer Wang from Tangshan Jiaheng Technology Co., Ltd. “It requires perfect synchronization of technology, communication, and trust.”

I recall two years of tracking metrics monthly for our client. This directly helped them pass their toughest safety certification test for a railway project. The challenging certification was for a specialized design we created which included anti- loosening nuts.

In the hardware sector today, OEM Services are no longer optional but rather a requirement. They serve not only as tools for tailoring an offering to a specific customer's needs, but also serve to strengthen competitive advantages in technology that competitors cannot easily replicate. The next time you have very specific requests for hardware, heed this advice: Standard solutions address average problems. OEM Services are extraordinary.