No.60 EastQingbei Road, High-tech zone, Tangshan city, HebeiP.R.China +86-15832531726 [email protected]

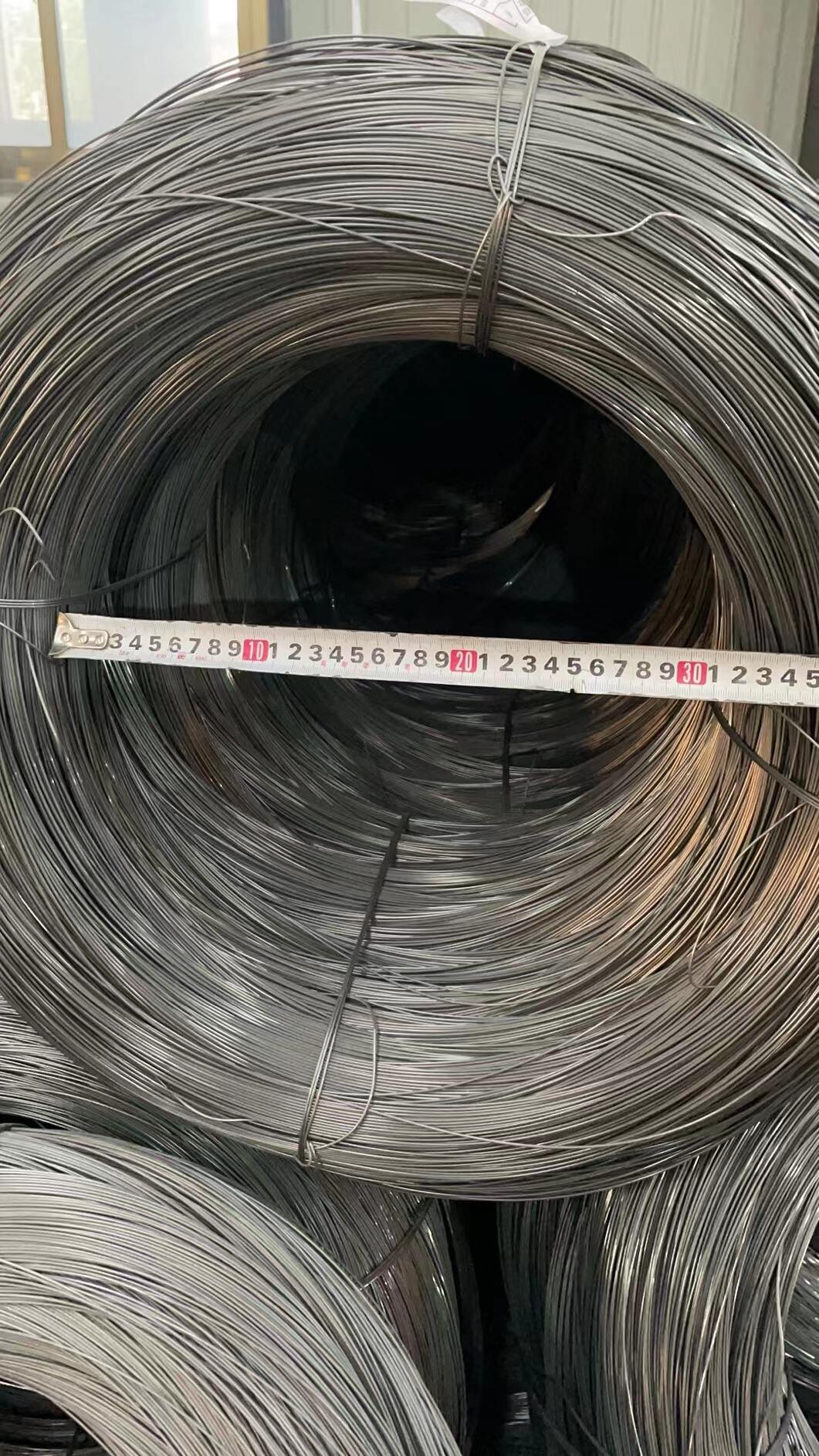

Black steel wire, an essential industrial material, represents a pinnacle of metallic engineering through its unique combination of strength, durability, and formability. This product is manufactured from low to medium carbon steel, which undergoes a specialized annealing process in a controlled atmosphere furnace. This critical thermal treatment, often referred to as "black annealing" or "open annealing," creates a layer of iron oxide (Fe3O4) on the surface, giving the wire its characteristic dark appearance. This oxide layer, while not a dedicated protective coating like zinc galvanization, offers a degree of inherent resistance to atmospheric corrosion during storage and handling before its final application. The primary advantage of black steel wire lies in its malleable nature, making it exceptionally suitable for subsequent fabrication processes such as further drawing to finer gauges, heat treatment for specific mechanical properties, or forming into complex shapes. Its surface provides an excellent key for paints, powder coatings, or other polymer finishes, allowing manufacturers to apply a customized final protective and aesthetic layer tailored to the end-product's requirements. In the furniture manufacturing sector, black steel wire is extensively utilized for crafting robust internal support structures, such as springs in upholstered sofas and mattresses. Its consistent tensile strength and ability to be cold-formed ensure these components can withstand repeated cyclic loading over many years. Beyond furniture, a prominent application is in the construction industry, where it is used to tie rebar in reinforced concrete structures. The wire's ductility allows workers to twist it securely by hand or with tools, creating a rigid framework that holds the rebar in place before concrete pouring, a fundamental process in building foundations, columns, and slabs. Another significant use case is in the agricultural domain for manufacturing baling wire, which is used to bind hay, straw, or cotton into compact bales for storage and transport. The wire's tensile strength is crucial here to withstand the immense pressures generated by balers without snapping. For projects requiring a specific finish or enhanced corrosion resistance, the annealed surface of black steel wire serves as an ideal substrate. Manufacturers can electroplate it with zinc for galvanization, coat it with PVC or other polymers for a colored and highly corrosion-resistant finish, or simply paint it to match specific design specifications. This versatility makes it a foundational raw material for a vast array of finished wire products. Given the wide range of potential diameters (gauges), tensile strengths, chemical compositions, and packaging options (coils, spools), the exact specifications and pricing are highly customized. We encourage you to contact our technical sales team with your specific application requirements, including the desired wire gauge, mechanical properties, and intended fabrication process. Our experts can provide detailed information on the most suitable grade of black steel wire for your project and guide you through our comprehensive product portfolio.