Understanding Drywall Screw Length and Its Impact on Structural Integrity

Why Drywall Screw Length Affects Wall Durability

The length of drywall screws really matters for how well the panels stay attached to the framing. Screws shorter than 1-1/4 inches just don't go deep enough into wood studs, which can lead to problems later on like walls sagging or developing cracks when pressure builds up. When using the right size screws, they should sink about 5/8 inch into the stud material but still sit flat against the panel surface. This setup keeps walls sturdy over time without leaving unsightly dents or damage to the drywall itself.

The Relationship Between Screw Length and Stud Penetration

Wood framing gets about 18 to 22 percent better grip strength when the screw length increases by a quarter inch, based on some structural tests we've seen. Metal studs tell a different story though. Most folks stick with shorter screws around 1 inch or just a little over that to keep from poking through the other side. Wood works best with something between 1 and 5/8 inches long generally speaking. Getting this right matters because it keeps things attached properly without accidentally damaging wires or pipes that might be hiding behind walls.

Common Mistakes From Using Incorrect Drywall Screw Lengths

- Overdriving short screws: Leads to head breakage and loose panels

- Undersized ceiling screws: Increases sagging risk—26% more common with 1" versus 1-5/8" screws

- Mixing screw types: Substituting sheet metal screws for coarse-thread drywall screws reduces holding power by 40%

How Building Codes Influence Recommended Drywall Screw Size

The International Residential Code (IRC) specifies minimum standards to prevent failures:

| Material | Minimum Screw Length | Maximum Spacing |

|---|---|---|

| 1/2" Drywall | 1-1/4" | 12" apart |

| 5/8" Fire-Rated | 1-5/8" | 16" apart |

Using non-compliant fasteners correlates with a 14% increase in drywall failures (ICC 2023), highlighting the importance of code adherence.

Data Insight: Failure Rates of Drywall Installations by Screw Length

NAHB’s 2022 analysis of 12,000 homes found a clear link between screw length and performance:

| Screw Length | Proper Penetration Rate | 5-Year Failure Rate |

|---|---|---|

| 1" | 58% | 22% |

| 1-1/4" | 94% | 7% |

| 1-5/8" | 98% | 3% |

Projects using 1-1/4" screws experienced 67% fewer callbacks for wall repairs compared to those using 1" fasteners.

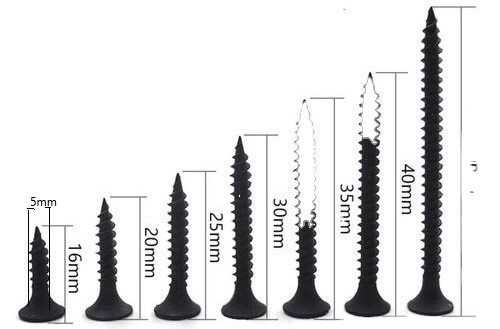

Matching Drywall Screw Length to Board Thickness and Application

Selecting the right screw begins with matching length to drywall thickness and application. Standard panels range from ¼" (curved walls) to 5/8" (fire-rated assemblies). For ½" drywall, use 1-1/4" screws; for 5/8", choose 1-5/8" screws—ensuring at least ⅓" embedment into wood studs for secure anchoring.

Ceiling installations demand 2" screws to counteract gravity and accommodate overhead driving angles, which can reduce effective penetration by up to 15%. The added length ensures full stud engagement despite ergonomic limitations.

Key guidelines by application:

- ½-inch panels: 1-1/4" screws for walls, 1-5/8" for ceilings

- 5/8-inch panels: 1-5/8" screws for walls, 2" for ceilings

- Multi-layer installations: Add â…“" screw length per additional layer

Mismatched screw lengths account for 62% of drywall failures, primarily due to under-penetration in thick panels or over-penetration in thin boards. Always measure both drywall and substrate before selecting fasteners to protect wiring and plumbing.

How Stud Material and Spacing Influence Drywall Screw Selection

Wood vs. metal studs: Differences in optimal drywall screw length

Wood studs require coarse-thread screws (1¼"—1⅓") to grip fibrous wood grain effectively. Metal studs, made of thin galvanized steel, need fine-thread screws (1"—1¼") to prevent stripping. The National Association of Home Builders recommends 25% shorter screws for metal framing to reduce the risk of puncturing concealed electrical or plumbing systems.

Impact of stud spacing (16" vs. 24" on center) on screw performance

With 16" on-center spacing, standard 1¼" screws suffice for most applications. At 24" spacing, longer screws (½" extra) are necessary to minimize panel deflection. For ceilings or high-load areas, pairing 24" spacing with 2" screws reduces sagging risk by 40% (Building Materials Journal 2023).

Strategy: Measuring existing framing to determine ideal drywall screw length

- Confirm stud material using a magnet or inspection hole

- Measure drywall thickness (typically ½" or ⅓")

- Add minimum â…“" embedment depth into the stud

- Round up to the nearest ¼" increment

| Application | Wood Stud Screw | Metal Stud Screw |

|---|---|---|

| ½" Drywall Walls | 1¼" | 1" |

| ⅓" Ceiling Panels | 1⅓" | 1¼" |

Trend analysis: Rise in metal stud usage and its effect on drywall screw selection

Metal framing adoption increased 18% from 2020—2023 due to fire resistance and cost stability (Construction Trends Report 2023). This shift drives demand for fine-thread and collated screws, especially in commercial and multifamily construction where speed and consistency are critical.

Avoiding Installation Errors with Proper Drywall Screw Sizing

Screw too short: Risks of poor anchoring and drywall bulging

Screws that don’t achieve at least ⅓" stud penetration create weak points, leading to bulging, seam cracking, or panel detachment over time. In seismic zones or high-impact areas, undersized fasteners increase the risk of structural drywall failure.

Screw too long: Penetration hazards through studs or wiring

Screws exceeding 1⅓" in standard 2x4 wood studs (actual thickness: 1½") can protrude into adjacent cavities, damaging electrical wiring or plumbing. Maintaining a ¼" buffer behind the stud minimizes this risk and aligns with best practices for finished wall safety.

Best practices for screw depth and spacing during installation

| Installation Factor | Technical Requirement | Common Error |

|---|---|---|

| Screw Depth | Head sits 1/32" below paper surface | Overdriven (tears paper) |

| Wood Stud Spacing | 12-16" centers | Exceeding 24" spans |

| Edge Screw Placement | ⅓" from drywall edges | Screws placed <¼" from edge |

Drive screws perpendicular to the surface until a shallow dimple forms—avoiding core damage. Space fasteners 8—12" apart along studs, tightening gradually to prevent stripping. In ceilings or moisture-prone areas, increase screw density by 15—20% to enhance durability under environmental stress.

Room-Specific Drywall Screw Recommendations for Home Renovations

Bathroom renovations: Moisture-resistant drywall and screw length needs

Use 1-5/8" coarse-thread drywall screws with moisture-resistant panels in bathrooms. This length ensures full stud engagement and supports double-layer or tile backer board installations. Corrosion-resistant screws are essential—27% of bathroom drywall failures stem from undersized or non-treated fasteners (NAHB 2022).

Living room and bedroom drywall screw selection strategies

For standard 1/2" drywall in living spaces, 1-1/4" screws provide reliable hold without risking contact with wiring or plumbing. Install every 12"—16" along studs and joists. In bedrooms with metal partition walls—common in 38% of modern designs—fine-thread screws offer better performance.

Garage and utility spaces: Heavier loads and structural demands

Garage ceilings supporting storage systems require 2" drywall screws to fully engage steel framing. For load-bearing walls with 5/8" fire-rated drywall, use 1-5/8" screws spaced 8"—10" apart. In utility rooms with mechanical systems, coarse-thread screws deliver 19% higher shear strength in wood studs (ASTM C1513 standards), enhancing long-term reliability.

FAQ

What is the importance of drywall screw length?

The length of the drywall screw is crucial because it determines how securely the panels attach to the framing. Proper screw length ensures durability, prevents sagging, cracking, and protects against damage to structures like wires or pipes behind the drywall.

Can using incorrect screw lengths cause drywall failures?

Yes, using incorrect screw lengths can lead to various issues such as loose panels, wall sagging, and increased failure rates due to inadequate or excessive penetration.

How do building codes influence drywall screw length?

Building codes like the International Residential Code set minimum standards for screw length and placement, helping to prevent drywall failure and ensure structural integrity.

What are the best practices for drywall screw installation?

Ensure screws penetrate at least 1/3" into studs, avoid overdriving screws, and follow proper spacing guidelines to prevent core damage or loosening over time.

Table of Contents

- Understanding Drywall Screw Length and Its Impact on Structural Integrity

- Matching Drywall Screw Length to Board Thickness and Application

- How Stud Material and Spacing Influence Drywall Screw Selection

- Avoiding Installation Errors with Proper Drywall Screw Sizing

- Room-Specific Drywall Screw Recommendations for Home Renovations

- FAQ